Cold Room Maintenance Checklist for UK Businesses

Introduction

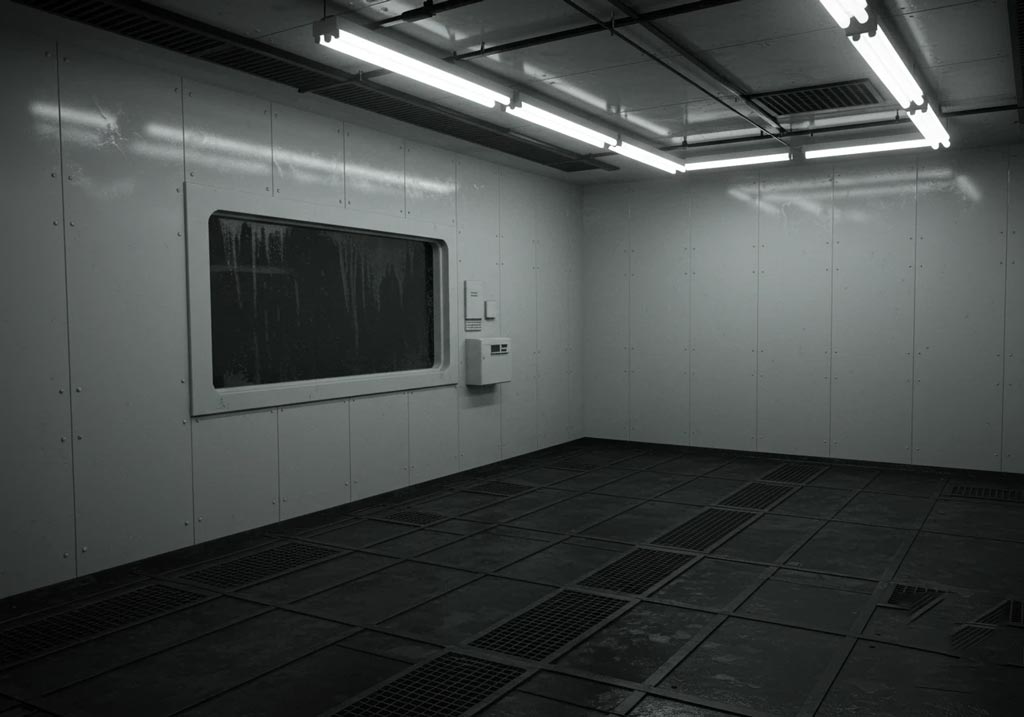

Cold rooms are essential temperature-controlled environments used across the United Kingdom in restaurants, supermarkets, hotels, production facilities, pharmaceutical storage and catering operations. They provide stable cooling, protect perishable goods, prevent bacterial growth and maintain product quality. Because cold rooms operate continuously, even small faults can cause significant issues, including stock loss, reduced energy efficiency and non-compliance with food safety regulations. Environmental Health Officers closely monitor these standards, making maintenance an operational priority.

Many businesses seek help only after a breakdown occurs, which often results in costly repairs and emergency call-outs. Proactive cold room maintenance improves reliability, reduces energy consumption, stabilises temperatures and extends equipment lifespan. The following checklist helps UK businesses recognise early warning signs and implement practical maintenance routines to minimise risk. If you notice any issues, contacting a qualified refrigeration engineer can prevent larger problems and protect thousands of pounds’ worth of stock.

Why Cold Room Maintenance Matters

Cold rooms are heavily regulated across the UK. Temperature instability, poor seals, excessive frost and drainage problems can lead to:

- Food contamination

- Failed inspections

- Rising energy bills

- Structural damage

- Operational downtime

Routine maintenance ensures compliance, reduces safety risks and supports consistent cooling capacity.

Explore our full refrigeration services:

https://mkrefrigeration.co.uk/our-services/

Daily Checks

Temperature Monitoring

Record temperature readings twice daily. Sudden fluctuations may indicate:

- Refrigerant leaks

- Failing compressors

- Faulty sensors

A standard chilled cold room should remain between 1°C and 5°C.

Door Seal Condition

Check for cracks, stiffness and gaps. Damaged gaskets allow warm air to enter, increasing frost and energy usage.

General Cleanliness

Remove spills and standing water. Keep walls and shelving clear to reduce mould growth and unpleasant odours.

Weekly Checks

Airflow Clearance

Do not store products against evaporator fans. Restricted airflow causes uneven cooling and humidity spikes.

Door Alignment

Misaligned hinges prevent proper closure and can damage seals, leading to ice build-up.

Coil Visibility

Look for dust or grease. Early detection prevents temperature strain on the system.

Monthly Checks

Condenser Coil Cleaning

Dust accumulation forces the compressor to run longer, increasing energy consumption. In high-traffic kitchens, monthly cleaning is recommended.

Fan Blade Condition

Unusual vibrations or rattling often indicates wear or debris trapped around blades.

Lighting

Broken bulbs can release unnecessary heat. Use LED lighting where possible.

Drainage and Condensation

Check drainage trays and pipes regularly. Blockages create:

- Pooling water

- Slip hazards

- Mould development

Condensation on panels signals poor insulation or failing door seals.

Humidity and Defrost Cycles

UK humidity levels, combined with continuous door activity, can overload evaporators. Signs include:

- Internal frost build-up

- Ice developing on fan grilles

- Persistent condensation

Automatic defrost systems should be checked quarterly.

Frost Build-Up

Frost affects:

- Air circulation

- Evaporator efficiency

- Energy consumption

Consistent frost formation indicates a deeper system issue. Seek professional assistance:

https://mkrefrigeration.co.uk/booking/

Floor and Wall Integrity

Insulated panels should remain rigid. Soft spots, discolouration or damp smells could indicate insulation failure, increasing energy waste and structural damage.

Evaporator Unit Inspection

Ensure fans spin freely and remain frost-free. Any unusual noise or vibration should be inspected promptly.

Control Panel and Alarms

Frequent alarm triggers mean temperature conditions are unstable. Digital controllers must be accurate for compliance, particularly in large UK cities such as London and Birmingham.

Improving Energy Efficiency

Energy prices fluctuate across the UK. To reduce operating costs:

- Install strip curtains

- Use automatic closers

- Clean condenser coils

- Upgrade to LED lighting

- Avoid prolonged door openings

Small improvements produce measurable savings.

When to Contact an Engineer

Contact a qualified refrigeration specialist if:

- Temperature fluctuates more than 2°C

- Frost appears weekly

- Drain blockages persist

- Energy bills rise unexpectedly

- Odours develop near door seals

Urgent help:

https://mkrefrigeration.co.uk/contact-us/

Common Cold Room Problems in UK Businesses

Businesses frequently report:

- Water leaks

- Excess frost

- Warm product surfaces

- Noisy evaporator fans

- Slow temperature recovery

- High energy consumption

Preventative care significantly reduces these faults.

Service Frequency Recommendations

For most UK facilities:

- Busy kitchens: Quarterly servicing

- Standard use: Bi-annual servicing

High-demand sites—particularly in London—may require additional checks.

Food Safety Compliance

Cold rooms must:

- Maintain stable temperatures

- Prevent cross-contamination

- Avoid moisture accumulation

- Use accurate digital logging

- Provide alarm systems

Neglect risks enforcement notices and product disposal.

Extending Lifespan

Simple practices extend cold room longevity:

- Train staff properly

- Maintain clear airflow

- Replace worn door seals

- Clean filters and coils

- Book scheduled inspections

Proactive care is cost-effective.

Do’s and Don’ts

Do:

- Keep ventilation clear

- Inspect seals monthly

- Log temperature changes

Don’t:

- Stack goods against evaporators

- Ignore water leaks

- Disable alarms

Frequently Asked Questions

How often should cold room temperatures be checked?

Twice daily to detect early deviation.

Why does frost return quickly?

Often caused by faulty gaskets, airflow blockages or humidity issues.

What temperature should a cold room be set to?

Between 1°C and 5°C depending on stock.

Is pooling water dangerous?

Yes, it promotes mould and damages flooring.

Do you offer nationwide maintenance?

Yes, including London, Birmingham, Manchester, Leeds, Bristol and Glasgow.

Conclusion

Cold rooms are essential for temperature-controlled storage across the UK. Regular maintenance prevents equipment failure, reduces energy usage, protects stock value and supports food safety compliance. By implementing daily, weekly and monthly checks, businesses can detect early warning signs and avoid costly emergency call-outs. When issues arise, contacting a qualified refrigeration engineer ensures rapid diagnosis and long-term reliability.

MK Refrigeration provides expert cold room maintenance, repair and installation, supporting UK businesses with nationwide coverage and 24/7 emergency response.

Contact MK Refrigeration

📞 Call For Services: (+44) 2037508743

✉️ Send Us Email: info@mkrefrigeration.co.uk

🚨 Emergency Call-Out: 07388 898148

🌐 https://mkrefrigeration.co.uk/contact-us/

Book a professional engineer:

https://mkrefrigeration.co.uk/booking/